SYSTEMS

FocalPoint Over-line System

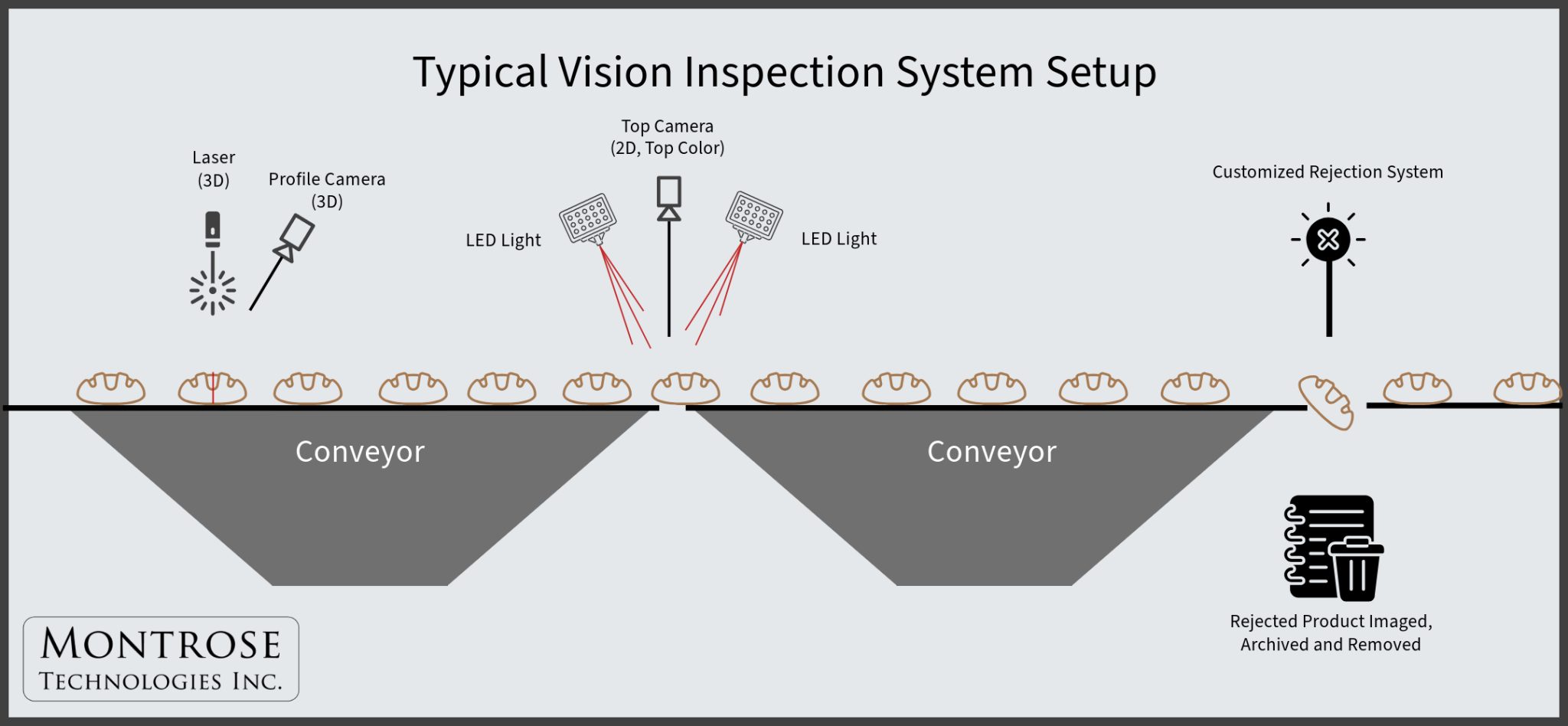

FocalPoint systems are fitted over an existing production conveyor to continuously monitor 3D and color attributes of all products produced.

FocalPoint Over-line Vision Inspection System Models

High speed, top only vision inspection with rejection for 100% of products

A FocalPoint vision inspection system is typically positioned just after the product is formed/baked/cooked, or just before packaging. At either location, the vision system can be configured to capture many product attributes, such as true color (top only), height, diameter, symmetry, length, width, and volume. The production data collected is available in real-time and is valuable to everyone in the facility to increase yields and maximize gross margins. Each FocalPoint turnkey solution is designed to fit the production requirements, environments, and line layouts.

The FocalPoint series of vision inspection systems quantify a wide variety of physical attributes and corresponding faults which may include:

- Diameter, Length, Width and Surface Area

- Volume

- Height, Slopes

- Crown and Heel Bake Color (excluding topping, split)

- Topping (color, coverage, count)

- Measures Color in L*A*B and BCU

The type and size of food product transported through the vision system will determine the number of cameras needed for the measurement requirements, the individual product rejection method, and hygienic/environmental considerations. Furthermore, FocalPoint Series over-line systems may include other customized material handling solutions such as automatic de-kissing of product, automatic box loading, and multi-route sorting.

The systems are easy to use, sanitize, and have a low annual maintenance cost. As a result, FocalPoint Series over-line vision inspection customers are largely self-sufficient.

Key Benefits

- Simple integration into existing production lines

- Measure over 150 objects per second with 100% inspection and rejection

- Measurement of product’s top 2D, 3D and true color

- Complete library of 100+ measurements

- Pre-configured with Montrose Inspection software customized for your products

- Rejection systems are customized to customer specifications, with various options available

- Real time data for individual faults

- Simple calibration takes less than one minute

- Fully configurable measurements, formula creation and rejection criteria

- Automatic generation and distribution of production, quality and rejection reports

- Payback is rapid, typically less than 12 months

System Functionality and Configuration

FocalPoint over-line vision inspection systems are designed to detect and perform measurements on a high volume of fast moving, randomly sized and oriented food products as they move along a conveyor at various stages of the process. These measurements are calibrated and produced in real-time, producing data to increase yields, quality and maximize gross margins.

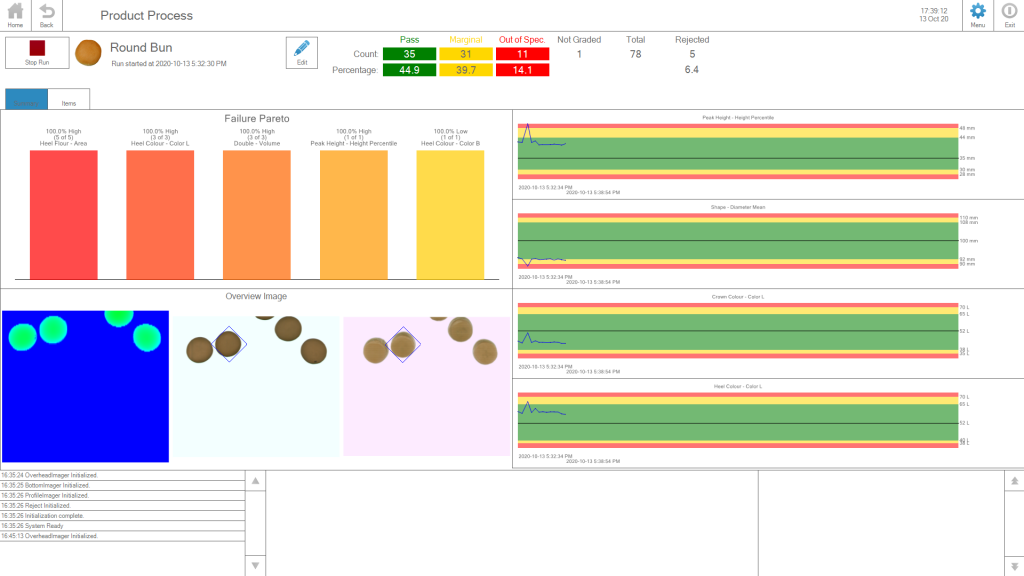

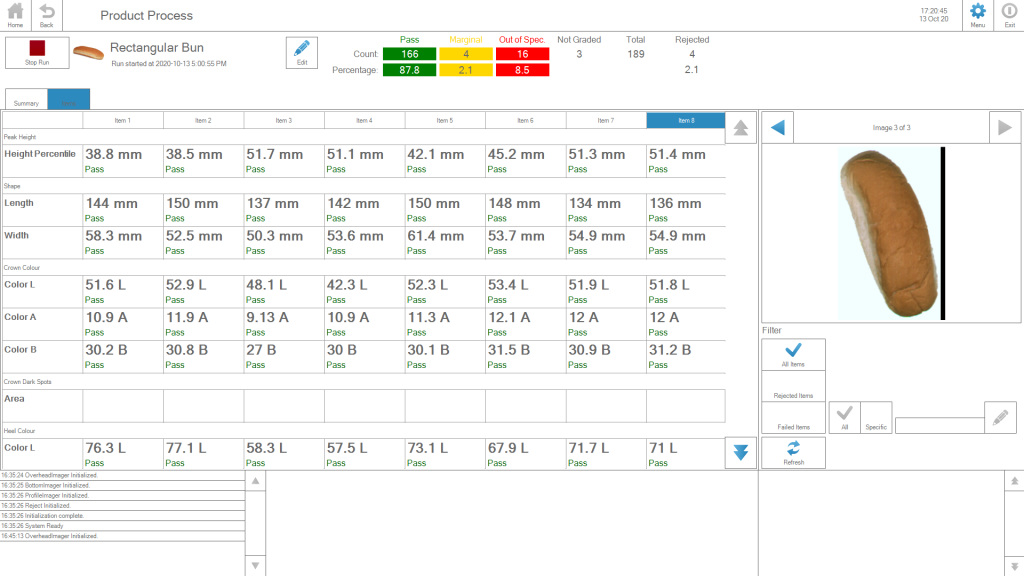

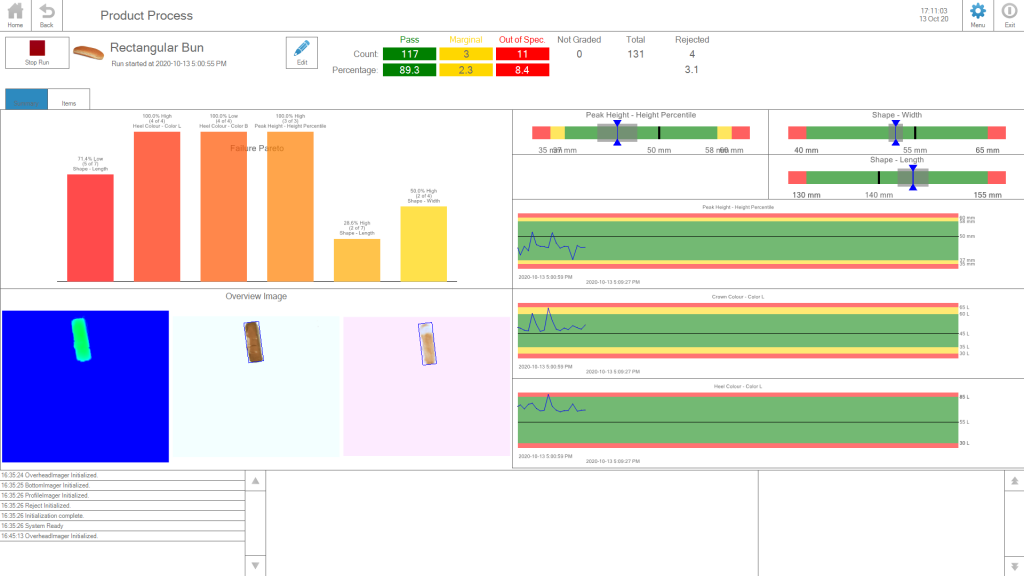

Systems are easy to use, with a modern, intuitive user interface which contains a comprehensive suite of measurement, analysis, reporting and archiving functions. The dashboard allows operators easy access to current results, trend graphs along with alarm conditions. More detailed information such as reject counts by result type and lane, histograms and measurement statistics are also available.

Once a fault has been detected, rejection systems designed specifically for the type of product being measured image the rejected product and remove it from the production line.

System options include conveyor belt (width, height, material), number of cameras, type of reject module, additional touchscreens, integration of third-party devices (scale, product handling), output signals to alarm and oven, and data output to plant-wide data systems and dashboard. Camera, lighting and laser placement is specified by the size and type of food product being measured. Montrose application specialists will work closely with customers to find the optimal solution to meet their specific specification.

Montrose Inspection Software

Montrose Technologies provides fast, accurate information to help you make money-saving decisions on product quality, wastage and production rates. The Inspection Software is a comprehensive suite of measurement, analysis, reporting and archiving functions designed to meet the needs of plant floor operators as well as developers and managers. On the plant floor, the software displays shape, size, dimensional, color and external data in a variety of graphical and numerical formats. Operators have fast and easy access to current results

Key Software Benefits:

- Simple operator interface (touchscreen-driven)

- Results displayed in numerical and statistical format

- Full data storage for averaged and individual object measurements

- Interfaces to external devices such as a barcode reader and temperature probe

- Can export raw data to other software packages (e.g. ERP)

- Supports unlimited lines and products

- Simple to setup, calibrate and operate

- Includes measurement data report generation

Improve quality, reduce production costs, provide valuable data.