SYSTEMS

SnapQC Benchtop System

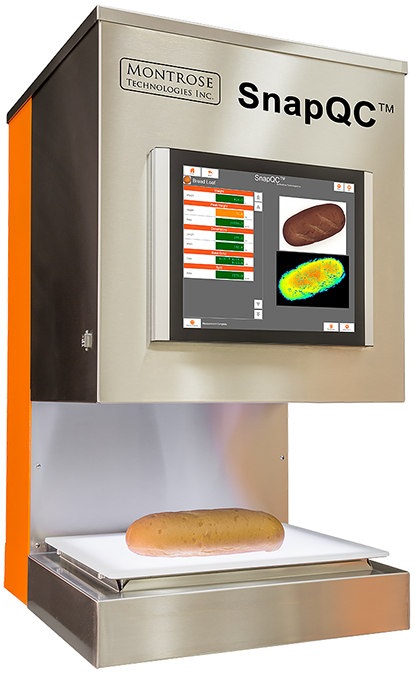

A complete, stand-alone 3D, color, and weight imaging system that instantaneously captures product attributes such as true color, height, diameter, symmetry, length, width, volume, and weight.

High speed, non-contact method to capture a wide range of object information.

The SnapQC vision inspection system provides quick, consistent measurement results, without the risk of human error. All data and images are instantaneously displayed and stored for reporting in the pre-configured Montrose Inspection Software. The system will measure multiple products at once, providing full image and measurement data for each individual item.

No other tool is able to compute all of these attributes on relatively large items, like a full loaf of bread, without the use of a conveyor.

The SnapQC benchtop vision inspection system for food production is utilized primarily by these groups in the food industry:

- Quality personnel responsible for periodic spot checks of product from production; in some cases before and after test bakes or enrobing.

- Ingredient developers/scientists

- Third party or corporate product evaluation service providers

- New product study and development

- Management personnel who want to fully understand the capabilities of a vision system before acquiring an over-line or in-line vision system

Key Benefits

- Physical measurement of products 2D, 3D, true color and weight characteristics

- Pre-configured with Montrose Inspection software customized for your products

- Measure multiple products at once

- Accurate, repeatable and reliable measurements in a Snap

- Full image and data storage, including automatic linking of multiple views (such as top and bottom) of the same products

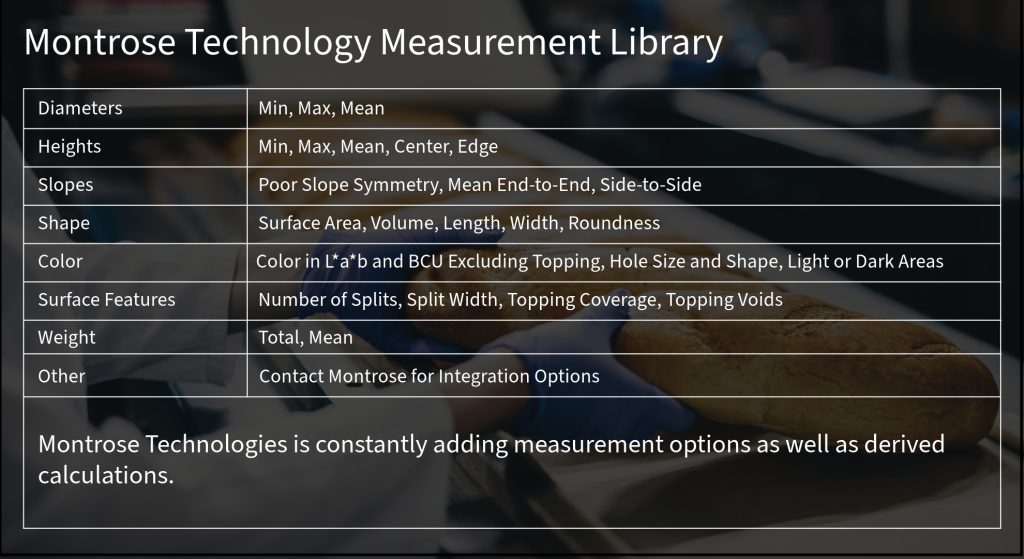

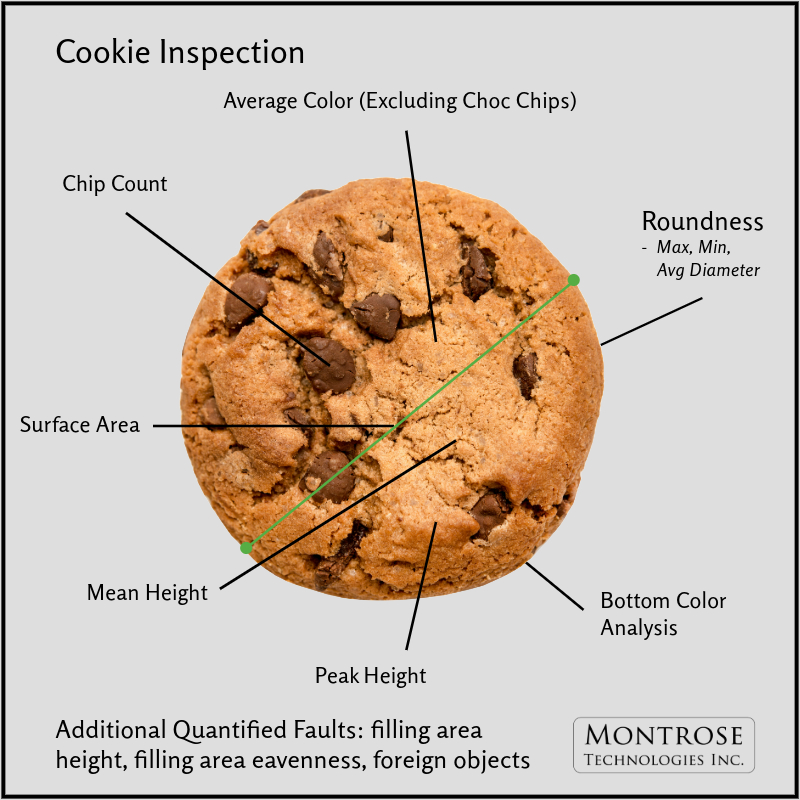

What Can Be Measured

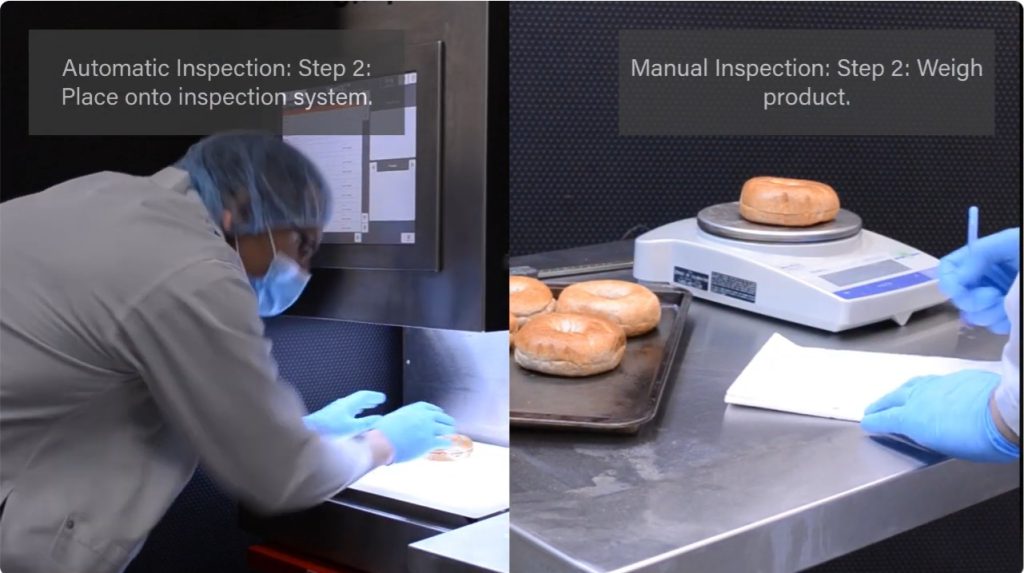

Vision inspection systems keep detailed records of each measurement. The SnapQC eliminates subjective and manual measurements, as well as manual data entry. As a result, there is rapid payback of the system cost through lower labor costs, time savings and consistent results. Sensory evaluation characteristics (such as aroma and taste) may be recorded in the manual entry portion of the SnapQC software. Several examples are listed below, which are just some of the 150+ measurements available in the standard SnapQC menu:

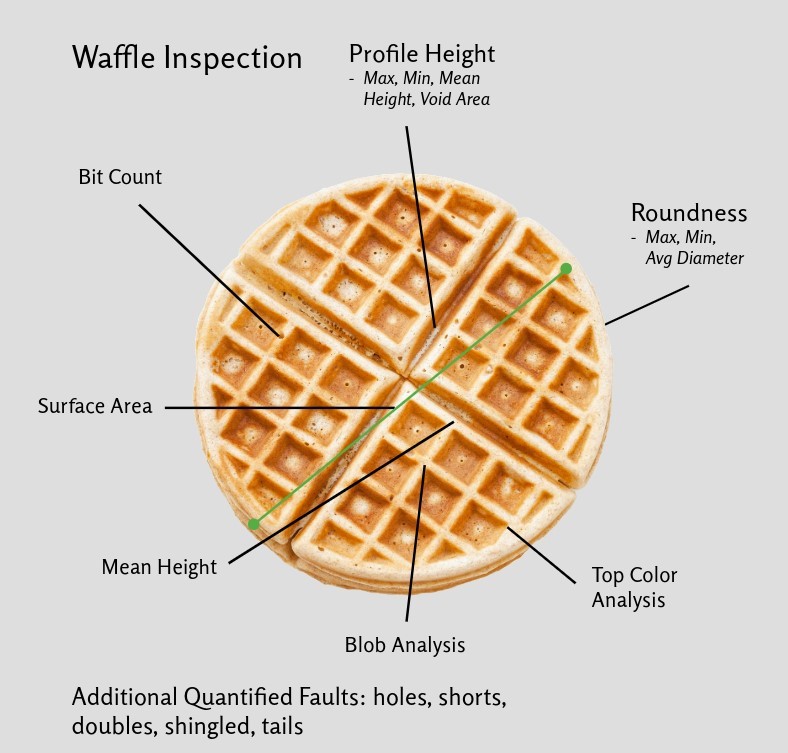

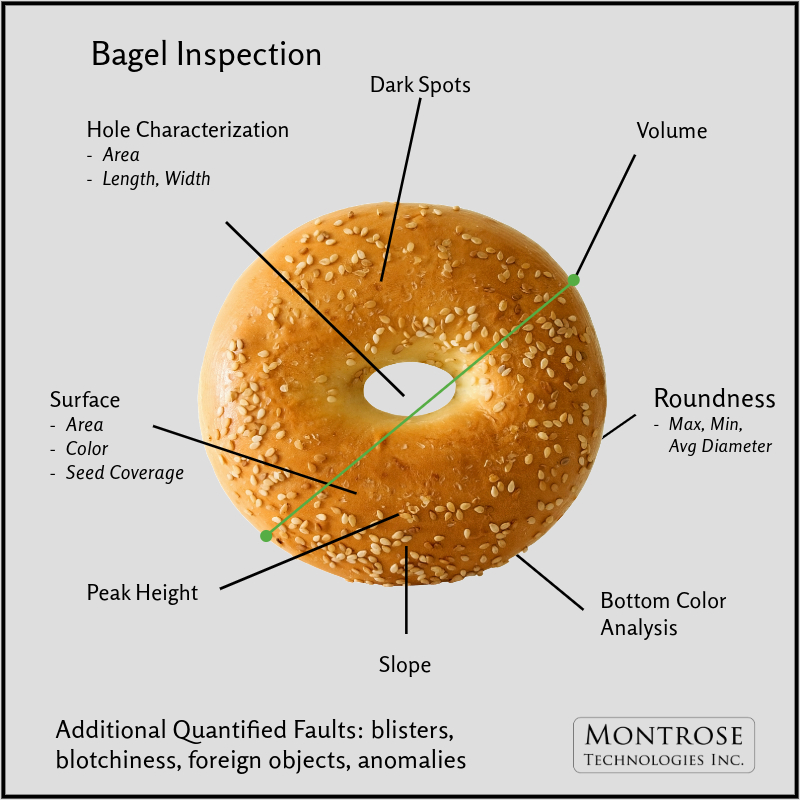

Below are three examples of common parameters customers request.

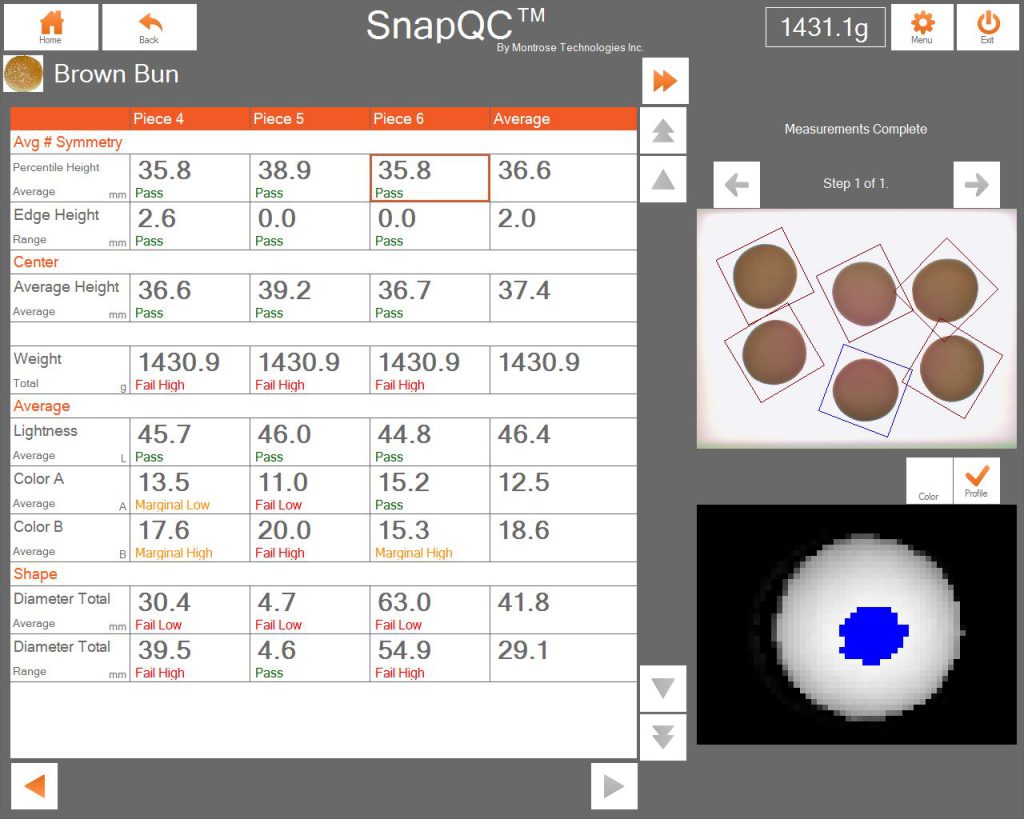

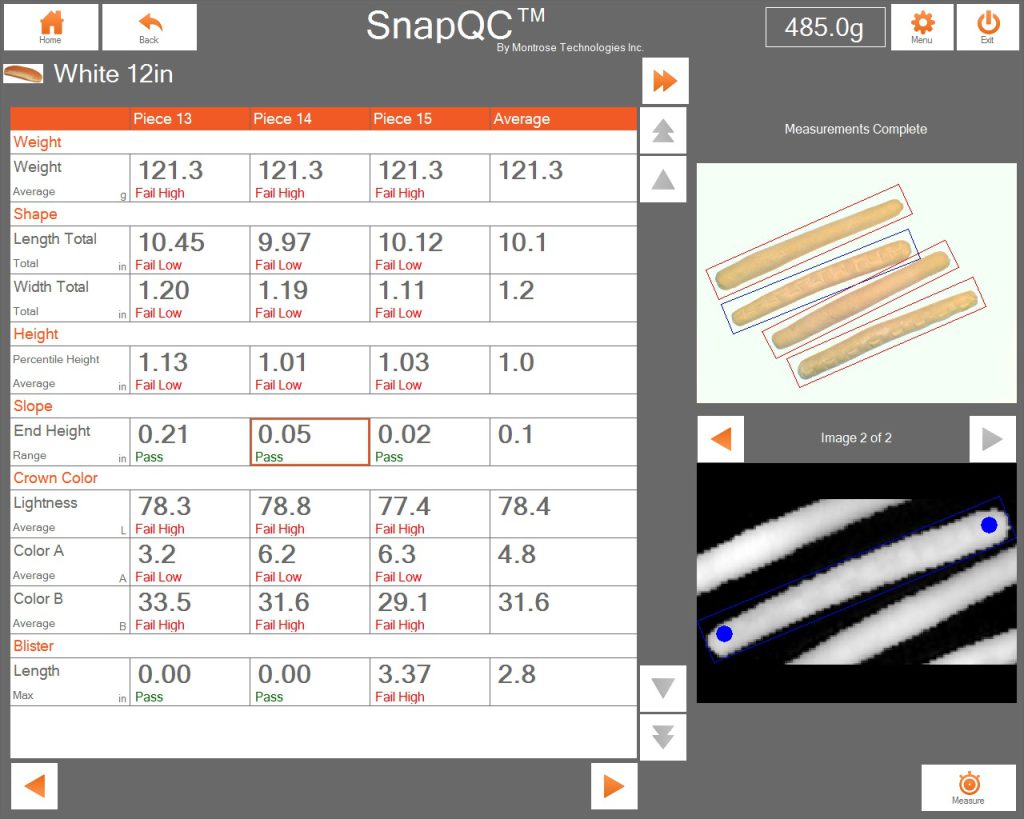

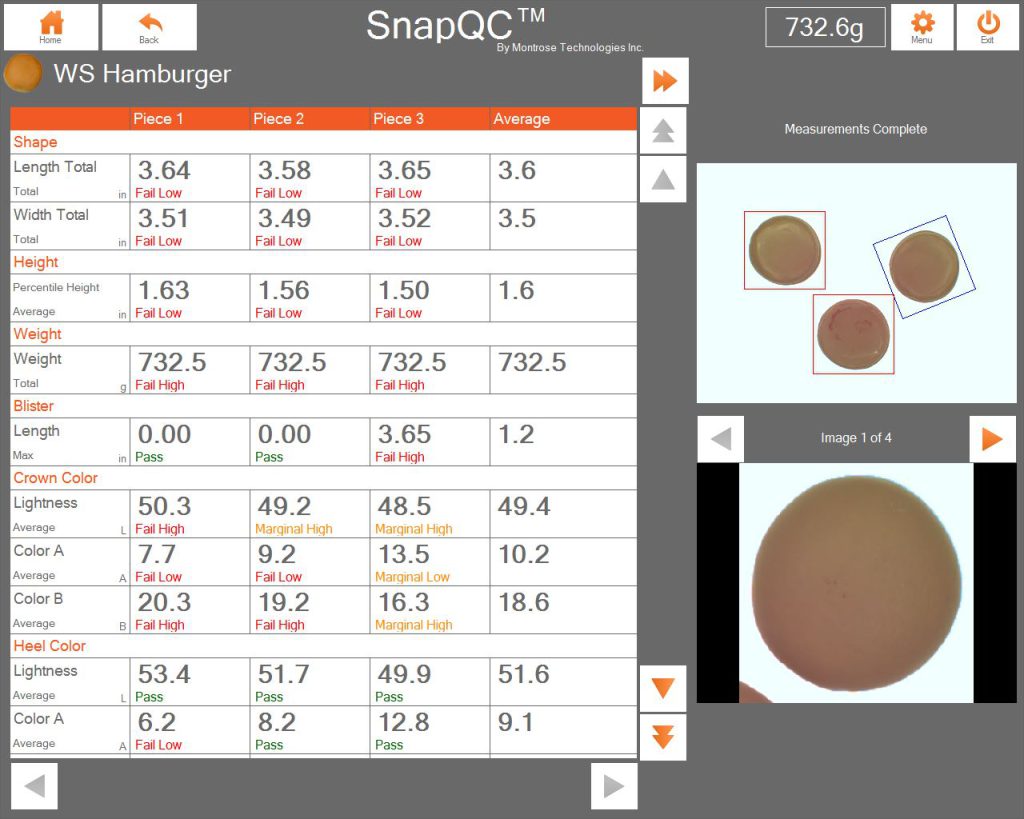

SnapQC systems measure shape and size through 2D measurements along with height, color and surface attributes using 3D and color imaging. Each bakery and snack food product uses specific product attributes specified by customers to meet their application needs. Solution sheets for common products can be accessed below.

Montrose Inspection Software

Montrose Technologies provides fast, accurate information to help you make money-saving decisions on product quality, wastage and production rates. The Inspection Software is a comprehensive suite of measurement, analysis, reporting and archiving functions designed to meet the needs of plant floor operators as well as developers and managers. On the plant floor, the software displays shape, size, dimensional, color and external data in a variety of graphical and numerical formats. Operators have fast and easy access to current results

Key Benefits:

- Simple operator interface (touchscreen-driven)

- Results displayed in numerical and statistical format

- Full data storage for averaged and individual object measurements

- Interfaces to external devices such as a barcode reader and temperature probe

- Can export raw data to other software packages (e.g. ERP)

- Supports unlimited lines and products

- Simple to setup, calibrate and operate

- Includes measurement data report generation

Improve quality, reduce production costs, provide valuable data.